-

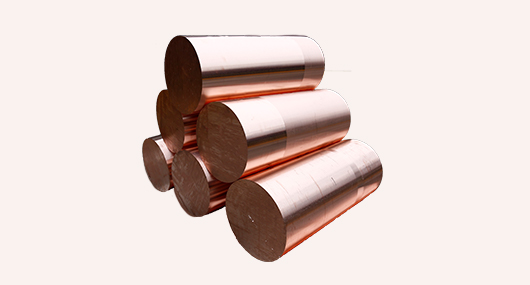

Copper alloy ingot

Copper alloy ingot is the key basic material for all kinds of copper alloy products. High quality ingot can guarantee the quality stability and cost control in the processing process, and help customers to produce high-quality copper alloy products with more market competitiveness.

-

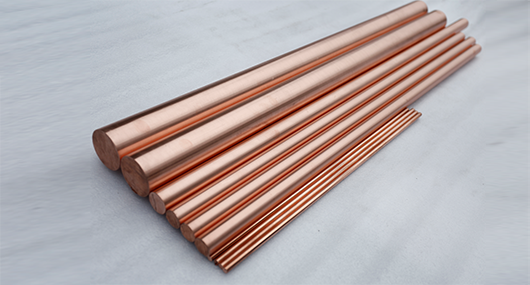

High strength high guide bar/plate

Market widely used with high strength and high conductivity bar/plates, through the special ingredients and the optimum technological combination, to achieve the strength of the material of conductive and perfect match, at the same time through trace elements added to improve the softening temperature of material, product specifications and diverse, dominated by customer demand, a variety of specifications can be customized billet and deep processing products.

-

End ring

High-speed rail transit motor rotor end ring (short circuit ring), as a part of the rotor winding, a general motor rotor needs two end rings (short circuit ring), the guide bar extended at both ends of the core with two end rings (short circuit ring) to connect all the two ends of the guide bar. It has good electric and thermal conductivity, high strength and high temperature softening resistance.

-

Conducting bar

The rotor guide bar of high-speed rail transit motor is installed in the rotor core slot, and both ends are welded with end rings (short circuit rings) to form a closed loop. It has good electric and thermal conductivity, high strength and high temperature softening resistance.

-

Shrinkage ring

Shrinkage ring is one of the important parts of the motor rotor. It is heated on the end ring (short circuit ring) and subjected to the tightening combining force, the centrifugal force of itself and the end of the winding, bending stress and so on. The superimposed stress is very high. It has high strength, high plasticity, high toughness, non-magnetic and minimum residual stress.

陕公网安备 61019002002481号

陕公网安备 61019002002481号